Cut Edge Corrosion Repair

Cut edge corrosion repair is a common requirement for commercial buildings, restoring the sheet laps of profiled metal roofs and cladding. If left neglected for too long, corrosion can lead to costly problems regarding health and safety, dilapidations and reputational damage. With our help, you can restore the condition of your commercial property with an advanced coating system designed for repairing and treating cut edge corrosion.

Problem: Cut Edge Corrosion

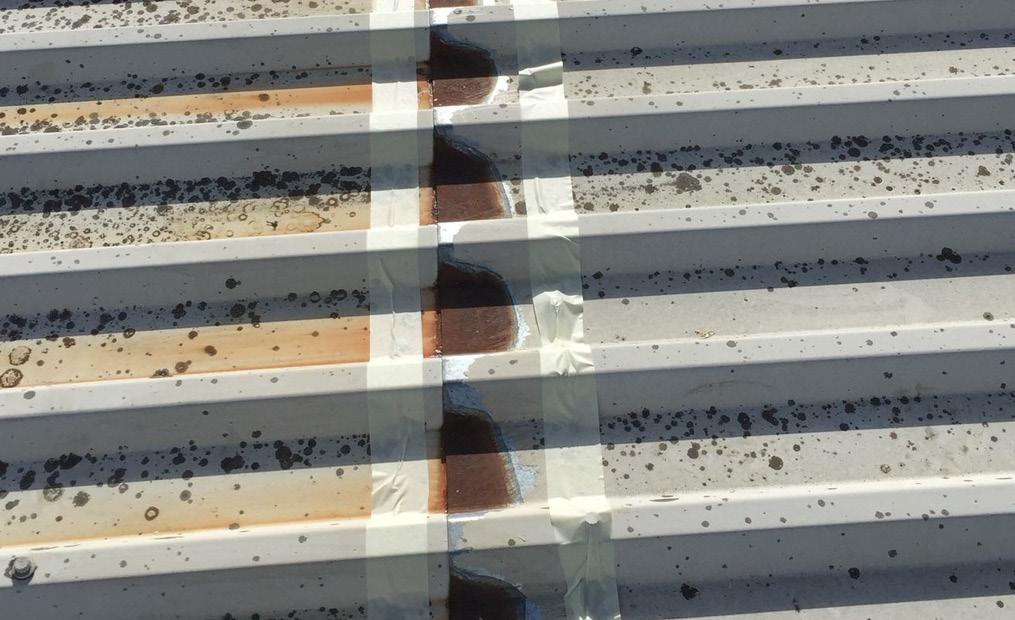

When profiled metal sheets are cut to fit the bespoke dimensions of a commercial unit, any factory-fitted protection against weathering is lost, leaving edges exposed to the elements. This is a particular problem at the lap joints as capillary held rainwater can begin to penetrate through protective layers, damaging sheets, fixtures and fittings.

Consequently, corrosion at the cut edges is often accelerated, and if left untreated for too long, can develop away from the edge, destroying the weather-sealed lap joint and gutter overhang.

Issues can often be seen in the form of edge peel, discoloration, blistering, spot corrosion and in severe cases, leaks and penetrating water damage. When this occurs, the advice is typically to replace profiled metal sheets, which can be costly, time consuming and disruptive.

Common Issues

- Capillary held rainwater at lap joints can accelerate corrosion

- Untreated corrosion can begin to develop further down profiled sheets, destroying joints and gutters

- Cut edge corrosion can cause significant damage, including roof leaks and health and safety concerns

- Replacing metal roof sheets and cladding can be costly

Solution: Cut Edge Corrosion Protection

The cut edges of a metal sheet need to be maintained to prevent corrosion. When issues are caught in time and a suitable cut edge corrosion treatment applied, this can avoid having to replace the entire metal sheet. Full replacement of large scale metal cladding or roofing systems is costly, time-consuming, and disruptive to the building occupants.

Benefits

- Cut edge corrosion treatments work by creating a barrier to protect against rainfall.

- Treating cut edge corrosion helps to preserve the integrity of the metal sheet.

- Using an effective treatment will help to avoid costly replacements.

Solution: Giromax® Edgecoat for Treating Cut Edge Corrosion

One of the most effective ways to treat cut edge corrosion is Giromax® Edgecoat. Designed to protect the cut edges of a metal sheet, Giromax® Edgecoat has several benefits.

Moisture tolerant, this treatment can be applied in damp conditions and provides a barrier against water at the cut edges. This formula will prolong the lifespan of industrial metalcladding and roofing systems, saving time and money on maintenance. Giromax® Edgecoatenables you to preserve the integrity of metal sheets and the original building aesthetic.

To preserve the integrity of your metal roof, use Giromax® Edgecoat for the treatment of cut edge corrosion.

Do you need help?

Our team is always on hand to provide further information for any queries you may have.

Talk to us