Giromax Cut Edge Corrosion Treatment

The Giromax team explains the design criteria governing the development of Cut Edge Corrosion treatment on Profiled Steel roofing.

CUT EDGE CORROSION TREATMENT – DESIGN CRITERIA

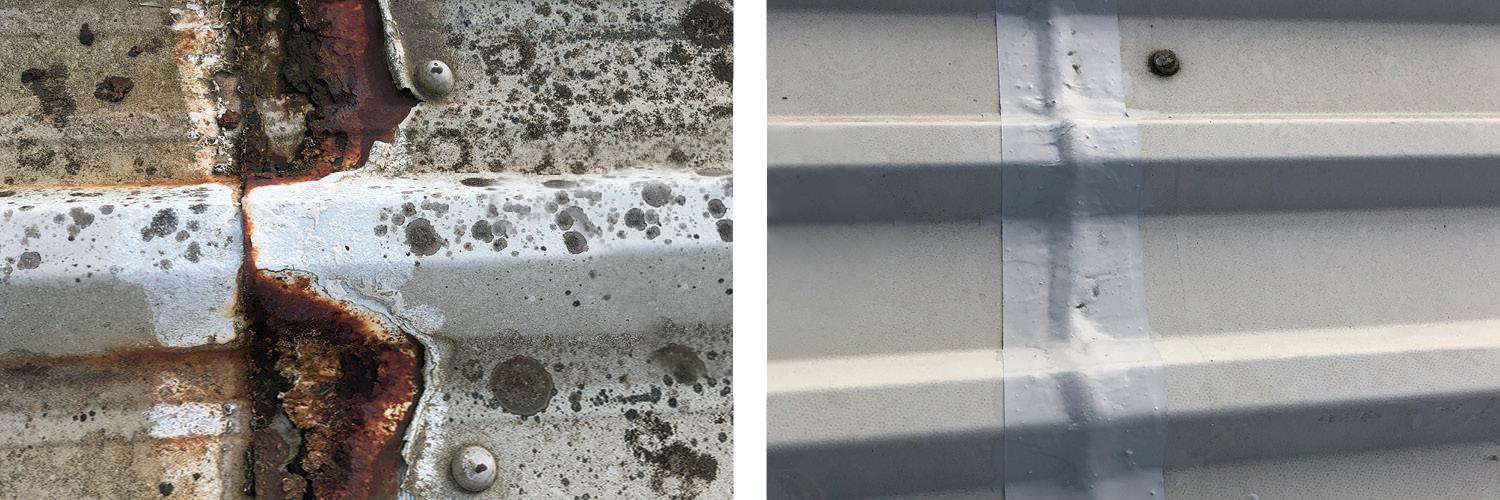

The lifetime of a profiled steel sheet is governed by the durability of its protective coating. Factory applied (pre-finished) coatings such as Plastisol eventually deteriorate and re-painting becomes necessary for continued protection of the steel substrate. Also within that coating lifetime, corrosion at the sheet cut edges can arise from normal weathering, especially at sheet overlaps, potentially affecting the integrity of that critical roof detail.

When treatment of the cut edge was first considered, the aim was to stabilise and where possible preserve the designed overlap until the roof sheet reached its repaint stage. It was realised that it was not sufficient to treat the corrosion on the outer surface alone. To prevent corrosion affecting the cut edge of the sheet, water held by capillary action had to be excluded from the lap.

In addition, failed experiments with tape soon exposed the fact that for the joint to remain sealed, the treatment had to be flexible enough to accommodate stresses from building movement, sheet expansion and foot traffic whilst also being able to withstand extremes of weathering, temperature, and UV.

To service this demanding specification a silicone based system was chosen, and at the time of its development, the specification design criteria also took into consideration the durability of the factory coating to which it would be applied as this would crucially govern its long term effectiveness.

Treatment depended entirely on the adhesion properties of silicone in being able to smother and starve the substrate of the two main agents of corrosion – air and moisture.

Using silicones, such adhesion can only be achieved on a completely dry surface and since moisture could not be fully displaced from the lap joint, adhesion could not be guaranteed with sealant alone.

The compromise was to augment the sealant with a brushable version, to form an external seal, the performance of which necessarily relied on the age and condition of the factory coating to which it was applied.

Experience had shown that corrosion could typically develop at the sheet cut edge between ten and fifteen years after installation, whilst contemporary manufacturers’ performance data indicated that plastisol had, at best, a durability expectation of no more than 25 years. Consequently, the guaranteed effectiveness of the silicone treatment could only be reliably assured for ten years at most.

Beyond that time, the factory coating itself was predicted to delaminate, allowing moisture to creep under both the weakened coating and the treatment to which it was adhered. Once contact with the steel substrate was re-established, the corrosion process would restart, and unless addressed in a timely manner, as for example during a scheduled roof repaint, significant repair or replacement of the original cut edge corrosion treatment could be anticipated.

To counter these limitations, Giromax have introduced a more technologically advanced solution.

Whilst factory coating performance has now seen dramatic improvements in life expectancy when sourced from market leading manufacturers, there remain many roofs sheeted with profiled steel bearing older or less durable coatings where the limited effectiveness of older silicone treatments could still prove to be an issue. To counter these limitations, Giromax have introduced a more technologically advanced solution.

Advances In Cut Edge Corrosion Treatment – Giromax® Edgecoat

For effective corrosion control, Giromax® does not rely solely on its tenacious adhesion. Nor does it have to rely on the durability of the factory coating.

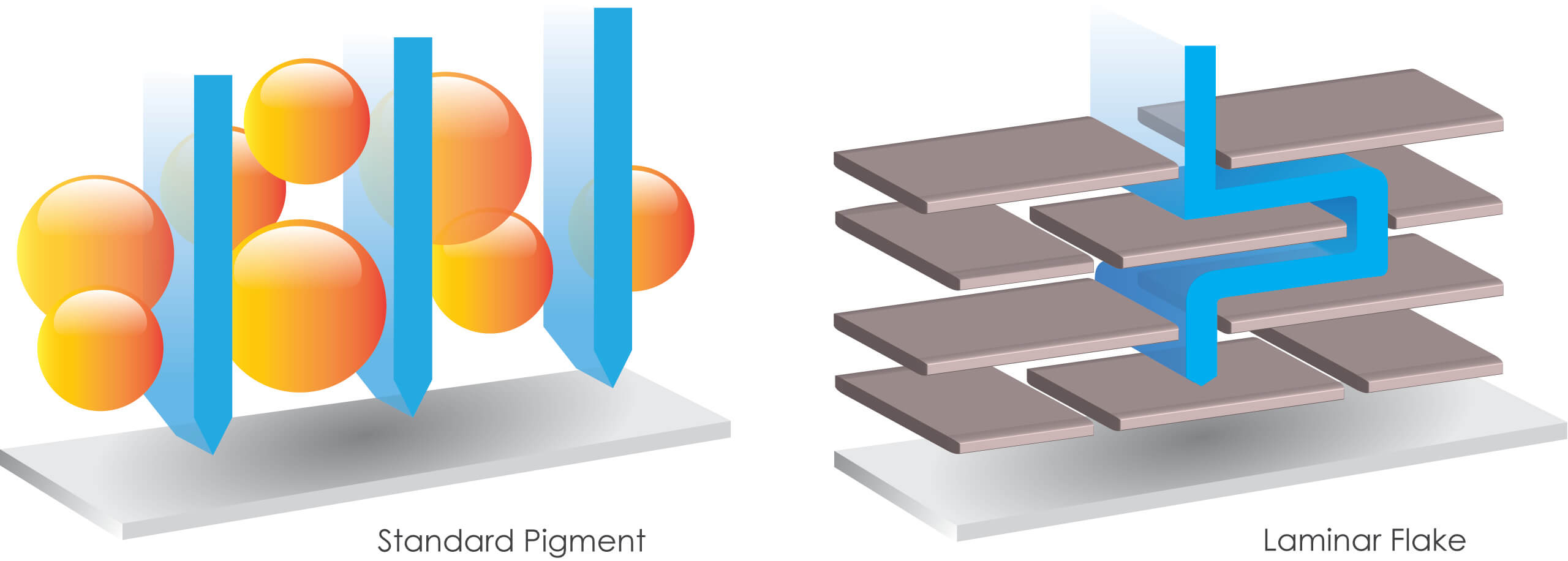

Giromax® Basecoat penetrates and binds with both corrosion and galvanised substrate at the molecular level, using laminar flake technology to form a hard barrier that prevents air and moisture from reaching the substrate.

Laminar flake is also found in Giromax® Sealant, a moisture tolerant sealant that fully contacts with all surfaces to secure a full inter-lap seal.

It uses the same base structure as Giromax® Edgecoat, the coating that completes the lap encapsulation that results in a tough, UV resistant system that fully satisfies the demand for both corrosion control and flexibility without sacrificing impact and abrasion resistance, securing the treatment of cut edge corrosion for roof sheet repainting when necessary.

Giromax® uses the latest hybrid technology that takes full advantage of properties developed to overcome the application restrictions and wear limitations of silicone alone. Fully moisture tolerant, the system can be applied to all surfaces, wet or dry, speeding up application times and helping meet project demands.

We’re always here to help, whether you want more information, a quote or are simply seeking some expert advice. Call our friendly advisers on 01455 558969 and enquire today.

Get updates from us

Sign up to our newsletter to receive all the latest news and insights from Giromax Technology.

Subscribe to NewsletterRelated articles

The Lifecycle of a Coated Roof

What is the typical lifecycle of a coated roof? Depending on the substrate, structure and the type of coating, the...

The Impact of Climate Change on Buildings

Climate change isn’t something that any of us can afford to ignore, especially when we consider the negative effects it’s...

Fire Safety and Industrial Roof Systems

Industrial roof fires may not always attract the same attention-grabbing headlines as those affecting domestic buildings, but the consequences can...